OGAB® Air edge®

Reduce downtime and maintenance cost for wind turbines using innovative Ogab® Air Edge® technology. Air Edge® helps prevent weather damage while preserving optimum blade aerodynamics and ensuring turbines stay safe and functioning even in freezing weather conditions.

Protecting wind turbine blades from the damage caused by the outside elements with our innovative Air Edge® technology.

Protect wind turbine blades with Air Edge® through two significant benefits. Firstly, prevent damage caused by the outside elements with our innovative technology that protects blades for a longer lifespan. Secondly, reduce the risk of downtime in adverse weather by using heated air pumped through nozzles and pipes in the system to prevent turbines from freezing.

Air Edge® Technology

Ogab®’s innovative system works by utilising custom-designed air nozzles and pipes across the wind turbine blades to create a protective air layer over the blade’s surface. This sheet of air creates a cushioning effect. The protective air layer can help protect the surface of the blade from erosion and surface damage caused by abrasive elements and harsh weather conditions such as hail, snow, and rain.

This air cushion not only protects against erosion, helping to prolong the lifespan of the blades and reduce maintenance and downtime, but on-demand warm airflow from the nozzles also helps the blades to maintain temperature to prevent the turbine from freezing and shutting down in extreme weather conditions.

Addressing Leading Edge Erosion

Over time, wind turbines can suffer from severe, leading edge erosion. Such erosion has prompted concerns about the long term reliability and costs of operation the wind turbines, especially those sited offshore.

Leading edge erosion also causes performance deterioration and additional maintenance costs. Furthermore, it also results in a substantial increase in the blade’s surface roughness. Subsequently, this affects the aerodynamics of the flow around the blades, which has a detrimental effect on the wind turbine’s efficiency.

As the wind turbine blade slices through the wind at high speeds, the fine particulate in the air, such as dust, ice, raindrops, hailstorm and snow, smash into the blade’s surface. Eventually, over time, these tiny collisions wear away the coating layer of the wind turbine blade surface and penetrate deeper into the blades.

Although the rotational speed of the wind turbines is not significant, due to their very long blades, their tip speeds are extremely high (in the range of 190-290 km/hr). This means that the collisions between rain droplets and blades are excessively abrasive. It’s not just leading edge erosion that reduces efficiency but also dielectric charges that lead to greater lightning damage as well as other aspects of wear and tear.

How Air Edge® Can Help

Using Ogab®’s breakthrough Air Edge® technology, it is possible to significantly reduce the concerns of leading edge erosion. By focusing on the decrease in erosion, we can help to increase the lifespan of wind turbines while also;-

Reducing labour, maintenance costs and operational downtime to offer an increased return on investment.

Powering Through Freezing Conditions

Another significant consideration for wind turbines is their downtime during extreme weather conditions. Wind turbines can be significantly impacted by weather conditions, especially freezing conditions. For example, in a severe winter storm in Texas in February 2021, almost half of the state’s wind turbines were frozen and unable to operate. The iced turbines had to wait until the storm had passed before they could function as normal.

To ensure consistent energy production and power output, turbines need to function in a range of weather conditions. Ogab®’s Air Edge® technology can help to ensure the power output of turbines during freezing conditions thanks to its innovative heating system.

The Air Edge® technology utilises air nozzles and pipes throughout the system, which can provide warm air on demand to help maintain the temperature in the turbine. This prevents the turbines from freezing, even in the most extreme of weather conditions.

How Air Edge® Can Help

Keep your blades turning even in freezing conditions with heated air nozzles in the Air Edge® system to reduce downtime and create energy when it is needed most.

Maintain your power output and protect your bottom line by reducing the risk of outages from extreme weather conditions with Air Edge® technology

Leading, Long-Lasting Wind Turbine Technology

The goal of operating wind turbine plants is to keep their aerodynamic characteristics for as long as possible in line with their original factory conditions. With the expectation of the long service life of the renewable energy harvesting technologies, maintaining such conditions for 20 years is crucial, but it is demanding.

How Air Edge® Works

Our breakthrough Air Edge® technology testing gives the solution to improve leading edge erosion rate in wind turbines by 47%. The system creates a unique cushion of air across the surface of the blades to give the blades another layer of protection, preventing damage from abrasion and erosion.

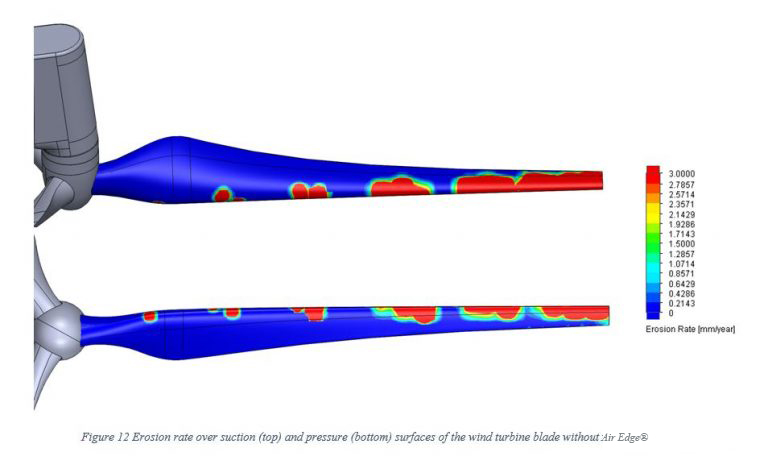

The figures below show the erosion rate on both of our test cases – with and without Air Edge®. As evident from this, a significant erosion rate exists across the leading edge of the wind turbine. This situation is more severe across the blade tip, where the tip speed is significantly higher.

Test case without Air Edge®.

In addition to this, without Air Edge®, the erosion is not only limited to the leading edge but also over the suction surface of the blade where there is significant erosion. The situation is milder on the pressure surface of the case without Air Edge®.

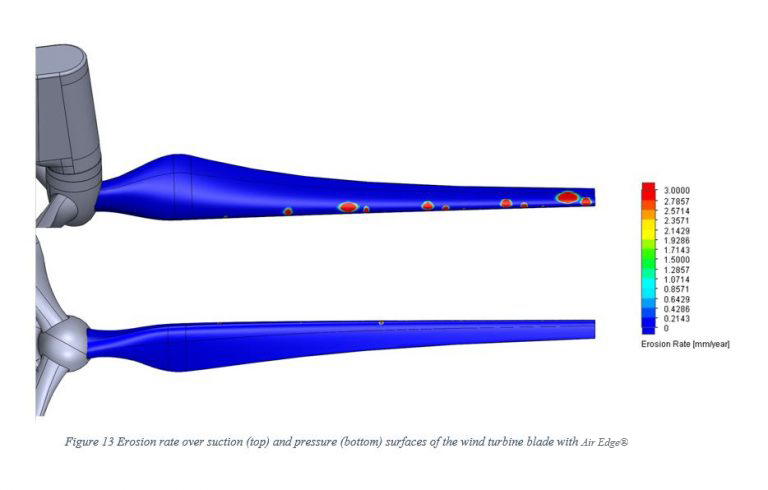

On the contrary, for the case with Air Edge® (Figure 13), there have been remarkable improvements in the blade erosion rate. Due to the implementation of our technology, the majority of the erosion has been eliminated on the pressure surface.

Overall, the affected areas have been reduced substantially as a result of applying the proposed Air Edge® concept to the leading edge of the wind turbine.

Test case with Air Edge® implemented.

It is evident from the presented results that the proposed Air Edge® system was an effective solution to the wind turbine erosion problem. It was possible to decrease the erosion rate of the wind turbine blade by around 47%. However, this should be noted that such improvement was achieved for the case of water droplets of a particular size and mass flow rate only.

The erosion rate can have higher or lower severity under snow or hail storms of different mass flow rates. However, from a relative perspective, we can conclude that Air Edge® can significantly extend the service life of the wind turbines and reduce maintenance costs and alleviate safety concerns.

Ogab® Wind Turbine Technology

Ogab®’s Air Edge® technology has shown to be vital in preventing power outages from freezing weather conditions while also significantly reducing the level of erosion to the blade. All of this helps to reduce downtime, maintenance costs, outages and cost to deliver greater efficiency and an increased return on investment.