OGAB® Downforce Generation

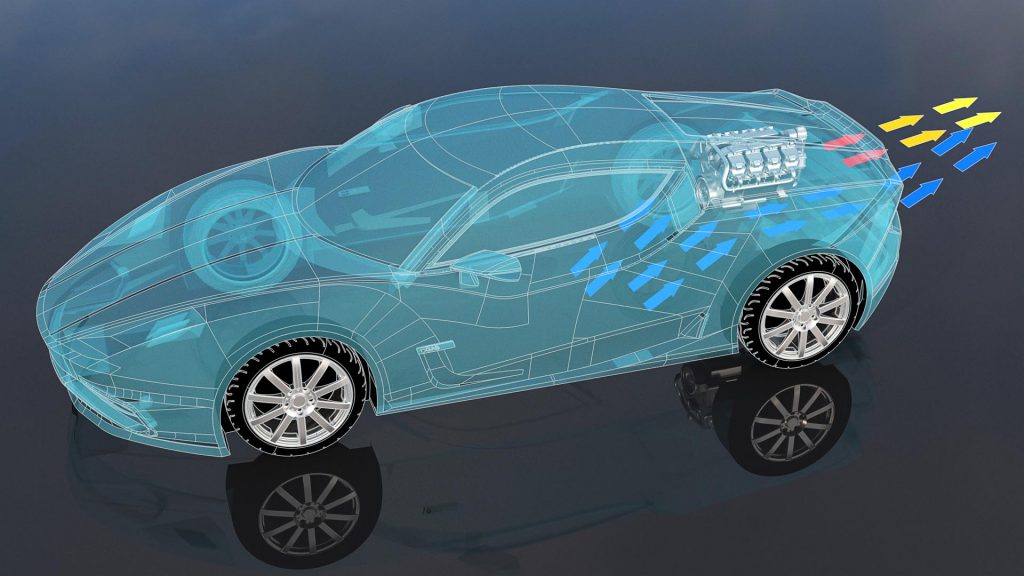

Ogab® present their unique downforce generation method for performance and racing vehicles. By utilising Active Flow technology, our novel patented system induces the air from underneath the car to then discharge in to the dead zone at the rear of the vehicle.

A pioneering system that meets the challenge of generating maximum downforce with minimum drag.

In the racing industry, the question of how to increase downforce on a car with minimum drag is the overriding challenge. It is mainly achieved through the efficient design of the bodywork and wings, which are examples of passive aerodynamic systems. The traditional bodywork elements like wings and spoilers, rely on the speed of the vehicle in order to be effective. The higher the vehicle speed the higher the downforce that can be generated.

As vehicles slow for corners, downforce is reduced, arguably at the time when the vehicle most needs it!

At the same time, it is well-known that drag increases with velocity, so the higher the speed the higher the drag against the vehicle. Hence, downforce (grip) and drag are conflicting parameters and adjusting parameters in favour of one of them will adversely affect the other. Often, race car design engineers seek for a compromise between these two parameters while implementing traditional aerodynamic components and techniques.

A Solution to Finding the Perfect Balance

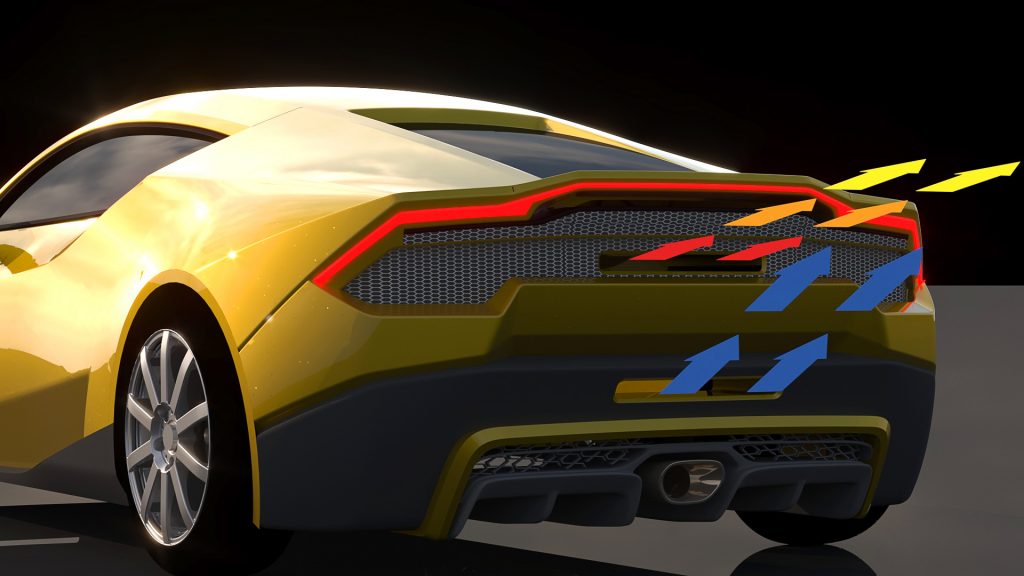

In racing competitions achieving a high downforce without increasing drag is vital in order to obtain the fastest lap times. Ogab® has achieved this by taking cold air from air amplifiers which is then injected into the active diffuser plenum. This then discharges through a specially designed narrow channel to generate the Coanda effect, which effectively creates an induced suction effect. This drags air from the underside of the vehicle through a channel and through the active diffuser before discharging into the dead zone behind the vehicle.

A New Direction for Performance Vehicles

Directing the discharged high density air in to the low pressure, low density region at the rear of the vehicle helps the existing turbulent air (that would otherwise create drag) dissipate, thus also reducing the drag.

Our research tests have shown that the system is highly effective, leading to a substantial reduction in drag. An improvement of 13.44% was achieved in the drag coefficient while downforce coefficient was increased by about 65.27% for the vehicle speed of 200 km/hr.

A Breakthrough Innovation in Aerodynamics

Conventional means of increasing downforce in racing competitions is often achieved via addition of extra weight especially in the rear region of vehicle. This will consequently lead to excessive tyre wears, which adversely affect lap times (and increases the costs of racing). the costs and adversely affect the lap times.

The Ogab® system of improvements in the drag and downforce were solely achieved by recovering the wasted exhaust air that is captured by the vehicle’s turbocharger. In other words, the excess air from the turbocharger that is not used in the engine cycle will be recovered for re-use either in drag reduction system or downforce escalation. Since, this technology utilizes the otherwise wasted energy without consuming any fuel, it outperforms other technologies in the market as majority of them require excessive power supply and often their gain is offset by fuel or power consumption.

Greener Racing

Excess tyre wear can result in harmful debris spreading into the environment. However, with our technology the right amount of downforce, generated at the right time without the need for additional weight can help to achieve a greener racing environment.

Ogab technology allows racing teams to create downforce consistently and cleanly.